Jacksonville, Florida (January 10, 2018)

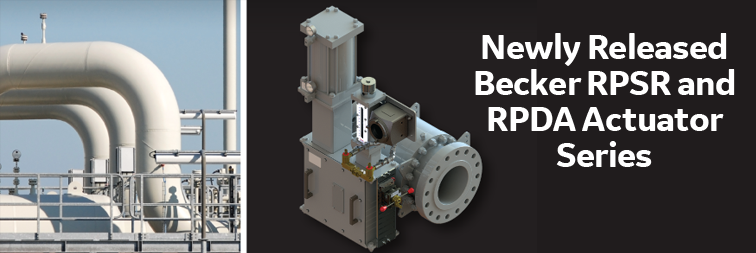

Baker Hughes today announces the release of a newly patented actuator design for ease of maintenance for pipeline and natural gas control applications. The new Becker RPSR (Rotary Pneumatic Spring Return) and RPDA (Rotary Pneumatic Double Acting) series of actuators now includes a series of enhancements that were developed from customer feedback to improve the ease of maintaining and tuning the valves in the field. Modular designs for torque arms and accessory mountings simplify design adjustments while holding tolerances in control to ensure a precision fit every time. Newly designed threaded holes in the torque arm allows the insertion of threaded torque hub removal bolts, which in one tightening motion pushes the torque hub outward to simplify the removal of hard to access components in the field.

“The Natural Gas industry has always been under scrutiny for environmental protection and safety.” Says John De Veau, Sr. Product Manager. “Our product development department addressed field safety by adding square housing assemblies with easy to access lifting points to ensure safer lifting and support of the valve assembly. Bolted covers were added with improved seal and precise gasket facing so we can continue to reduce the carbon footprint of the pipeline control valves.”

The new RPSR and RPDA actuators series further expand the portfolio of Becker natural gas control valve products, and continue to drive our message to improve the challenging applications with Becker products that are SIMPLE, PROVEN, AND SAFE FOR OUR ENVIRONMENT.

For more information on Baker Hughes-Becker portfolio of natural gas control products, please visit out links below.

https://valves.bakerhughes.com/becker