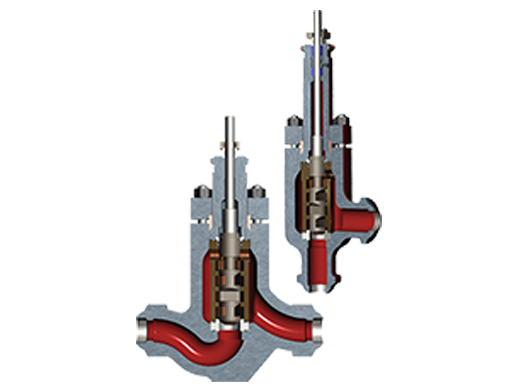

Masoneilan 78400 / 18400 Series LincolnLog™ Anti Cavitation Valve

Applicable Industries

Power Generation, Refining, Midstream Oil & Gas, Upstream Oil & Gas, Pulp/Paper.

Key Applications : Reactor Building, Turbine Building, Reactor Facility Grounds & BOP, Heat Recovery Steam Generator, Balance Of Plant, Hydroprocessing, Cracking, Pipeline Integrity,Operations,Refrigeration, Liquifaction, Loading/Shipping, Regasification, Auxillary, Seperation, Dehydration/Treating.