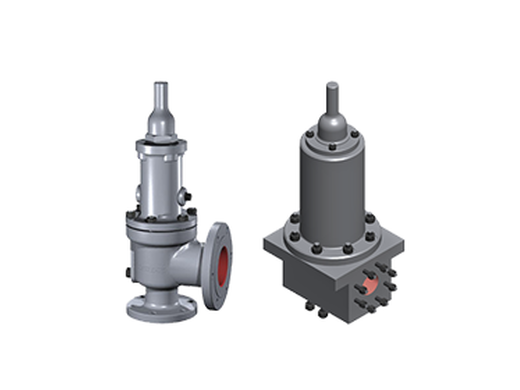

Consolidated Type 1900 Dual Media (DM) Safety Relief Valve

Applicable Industries

Power Generation, Refining, Petrochemicals, Midstream Oil & Gas, Upstream Oil & Gas, Paper.

Key Applications : Cooling Tower, Reactor Building, Turbine Building, Reactor Facility Grounds & BOP, Gas Turbine, Heat Recovery Steam Generator, Balance Of Plant, Distillation, Hydroprocessing, Reforming, Cracking, Secondary, Blending, Quenching & Fractioning, Charge Gas Compression, Separation, Pipeline Integrity, Dehydration, Auxilary, Dehydration/Treating, Compression.